A magnet is defined as an object which is capable of producing a magnetic field and attracting unlike poles and repelling like poles.

There are many types of magnets, which are generally divided into two categories: hard (permanent) magnets (magnetic retention for a long or permanent time) and soft magnets (magnetic for a short period of time). The magnets we call generally refer to permanent magnets.

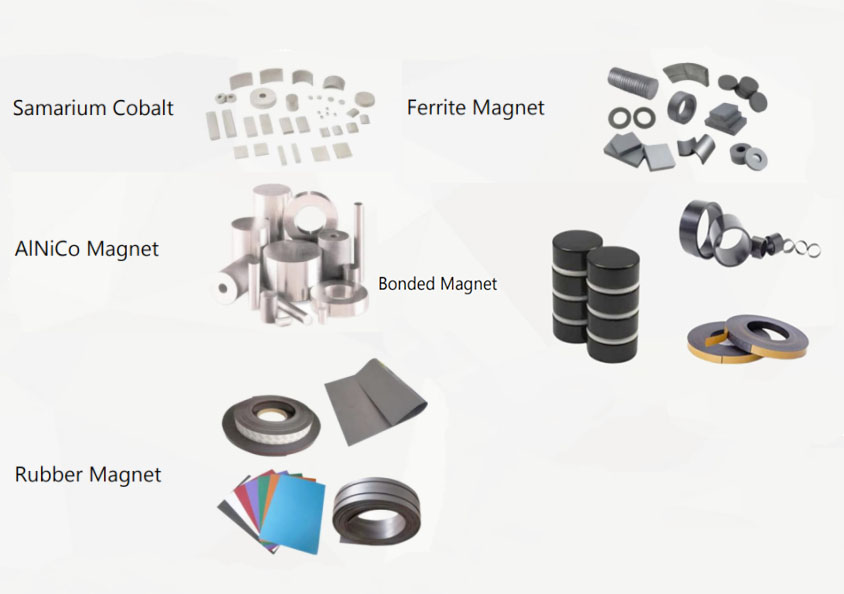

Magnet classification

Magnet Sort by material

(1) Alloy permanent magnet material

Including rare earth permanent magnet materials (NdFeB Nd2Fe14B), samarium cobalt (SmCo), aluminum nickel cobalt (AlNiCo)

(2) Ferrite permanent magnet material (Ferrite)

Magnet sort by shapes.

Tile-shaped magnets(Arc shape), special-shaped magnets, cylindrical magnets, ring magnets, disc magnets, block magnets, and various shapes can be punched holes.

Classification by production process

Rare earth permanent magnet material

Magnets applications

1. Electroacoustic field: speakers, receivers, microphones, alarms, stage audio, car audio, etc.

2. Electronic appliances: permanent magnet mechanism vacuum circuit breakers, magnetic latching relays, watt-hour meters, water meters, sound meters, reed switches, sensors, etc.

3. Motor field: VCM, CDDVD-ROM, generators, motors, servo motors, micro-motors, motors, vibration motors, etc.

4. Mechanical equipment: magnetic separation, magnetic separator, magnetic crane, magnetic machinery, etc.

5. Healthcare: nuclear magnetic resonance apparatus, medical equipment, magnetic therapy health care products, magnetized fuel saver, etc.

6. Other industries: magnetized wax inhibitor, pipe descaler, magnetic fixture, automatic mahjong machine, magnetic lock, door and window magnet, luggage magnet, leather magnet, toy magnet, tool magnet, craft gift packaging, etc.

KENENG is an excellent custom magnet manufacturer. We can manufacture neodymium magnets, permanent magnets, magnet rod and other magnets of different materials and shapes. We have 15 years’ experience in magnets design, manufacturing, coating, and export all over the world, we have won a good reputation in this industry for our excellent and stable quality, prompt delivery, and fast response.

KENENG support customizing making low-temperature and high-temperature resistant magnet assemblies, making general materials and special materials, and strong magnetic.

Various finishing methods

1. Zinc plating (bright and clear film with low corrosion resistance)

Used in high temperature and slightly corrosive conditions or limited anti-corrosion occasions where the surface is resistant to short-term pollution and discoloration

2. Zinc plating layer (rainbow or dark film with higher corrosion resistance)

Used in harsh atmospheric environments and high-demand anti-corrosion occasions

3. Nickel plating layer (including copper + nickel plating layer)

Exposure to the indoor atmospheric environment where condensation may occur, and it is required to ensure long-term stability and long service life of appearance and internal performance.

4.Nickel + tin electroplating layer

For the occasions where the surface can be soldered and electrically contacted

5. Phosphate layer

It has a certain short-term rust prevention ability, which is used for unfinished halfway transportation and rust prevention of short-term storage. The more ideas come from you, the more chances to change the world.