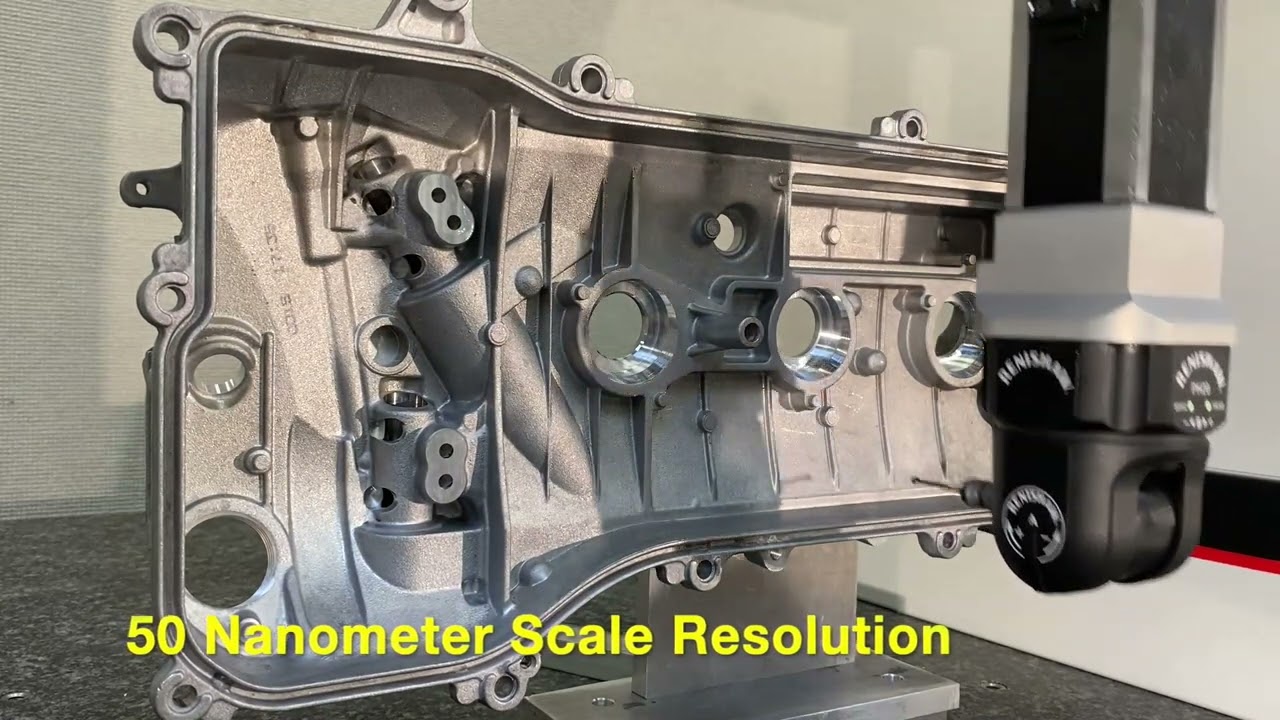

In today's Metrology Cafe, we ask that you make yourself comfortable. Today, Allen is going to provide a discussion on some of the most significant characteristics and advantages of the ph 20. It is an index probe that already incorporates a tp20 touch probe, and it is designed to work with the tp20 module that is already installed. When you use the em1 or em2 module, you can even get a greater range, and it has the same level of collision protection as the tp20 magnetic module. As a consequence of this, the head is furnished with the capacity for infinite positioning and motion along all five axes, just like Renishaw's revo multi-sensor system. The touch probe is the only one of the five-axis probes that should be used, while the analog probe should not be used at all. The angles that are measured along axes a and b rotate due to the circumstances of this particular scenario.

Because of this, the probe is able to collect data even when the CMM is kept still. This opens up a great deal of potential for increasing production speed while also improving accuracy. My first point of discussion is going to be about the infinite number of different ways in which PH 20 can position itself in the world. In contrast to the ph 10, it can rotate in both the positive and negative directions along the axis, as well as rotate 115 degrees in either direction. Additionally, it can rotate 115 degrees in either direction. However, the b axis truly does have an infinite range because it is able to rotate the positioning function in any direction and without limitation. This means that it can be thought of as having an infinite range. This makes it possible to access functions in the most efficient manner possible and reduces the number of times throughout the program that a fresh stylus is required. When compared to other, more traditional types of professional pets, almost all high-altitude parables are completely negligible and can be ignored. Inferential calibration is the name given to one of the distinguishing characteristics of this type of calibration because of this reason.

Therefore, rather than selecting the probe angle we want to calibrate independently, we can obtain all of the available positions by running a program that plots the head. This allows us to save time and effort. Because of this, we will be able to see all of the positions that may or may not be available. However, if you really need the most accurate positioning accuracy, we can calibrate the tip using the ph 10 mode just like your traditional calibration if that is what you would prefer. This is only an option if you really need the most accurate positioning accuracy. It makes no difference whether we have crank eyes or disc eyes; the procedure that we must follow remains the same. Therefore, if you have a very complex part, there are many characteristics in many different directions on the side of the part, which will be a huge benefit to you because you will start and run the CMM Inspection Companies in about five to six minutes, so various methods are summarized in the chart, and almost all of the cases you see here are straight. If you have a very complex part, there are many characteristics in many different directions on the side of the part, which will be a huge benefit to you because you will start and run theCalibration appears to be the method of choice, based on what I can infer from this.

I'd like to bring to your attention the fact that the special styles, such as the crank or the disc, can only be calibrated by touching the head of the instrument. I hope that this information is helpful. They are incapable of employing the inference method in their work. As a consequence of this, Finish also offers a summary of these suggested calibration methods, in addition to the performance that can be anticipated in a variety of applications (ranging from 1 to 2). It is possible that you will need to calibrate using ph 10 once more if the error is relatively small. The 20 stylus now has a diameter of 4 mil, though it can be shrunk down to 1 mm if necessary. There is no reason for us to switch to the ph 20 stylus given that we already use the ph 10 model.

My head can be tilted in a variety of positions; therefore, if I only use a particular setting angle and use cmf to touch one thing we noticed, that is, through conventional detection, you can get tremendous throughput improvements. This is due to the fact that when measuring a part with the greatest advantage of unlimited positioning, a deep or narrow hole must be taken into consideration in order to check the minimum gap between the stylus or probe module and the part features. To demonstrate that Renishaw put together this content, and they played a game between ph20 and ph10, this is especially true on smaller parts, particularly on smaller prismatic parts with many features on different sides. This is especially true on smaller prismatic parts with many features on different sides. Our team came to the same conclusion regarding the total number of clicks. Although the information is still shown on the left side of the screen, it has been moved to the right side of the display. The motion parameters have not changed significantly.

It will be possible for you to recycle each and every piece of TP20 that is currently being utilized. It is time for me to join Adrian in talking about some questions and answers, CMM Inspection Companies and the conversation is currently in progress. You have been a tremendous help, and the quality of the information is outstanding. It would appear that there are a number of questions associated with this topic. What kinds of machinery are essential for working in an environment with a pH value of 20? Actually, you're right. Many thanks to each and every one of you.

This is very nearly the last question that needs to be answered. At this stage, we are deciding which head angle will be calibrated, and the machine will perform an individual calibration for each angle. As a consequence of this, a 90 b90 will be incorporated into this routine if it is stipulated that we must complete one. If 90b9 is used as the standard for calibration, then the internal error of the whole head will be plotted. Because of this, you can rest assured that every single conceivable position will be calibrated. This is a reasonable explanation for the reason why. . . It has just a slender link to ph 20, which is not very significant. Due to the fact that it is a TP20 module, you are acting in the capacity of a touch trigger probe.

If, on the other hand, scanning with the five-axis technology is something that piques your interest and you want to learn more about it, you should investigate it and perhaps visit rev. It enables the capability of searching the entirety of the world. It's possible that this is something that can be covered in one of the other sections of the content. revo has the ability to conduct its own scanning independently. That seems like a good plan.